Locomotive Boiler - Construction, Working Principles With Advantages and Disadvantages

Application, Construction, Working Principles With Advantages and Disadvantages of a Locomotive Boiler.

Before we go further let's learn about why the Locomotive Boiler means by this name. A locomotive is a self-propelled vehicle and it can be powered by Diesel, Electricity, or Steam. This type of Locomotive Steam engine was famous in the railway sector in different countries. You may see several Locomotives in a historical Hollywood Movie where an engine operator throws solid coal inside the boiler furnace. And boiler is a part of the Locomotive where steam is generated to power the Locomotive engine. This boiler can generate enough steam with high pressure that carry enough standard passenger and cargo train bogies.

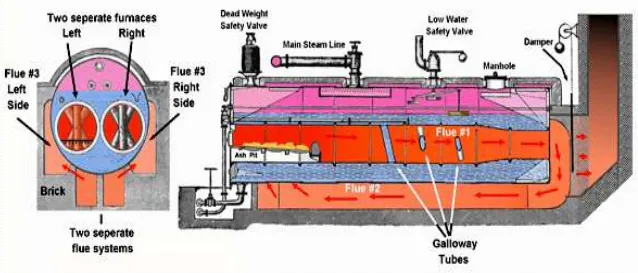

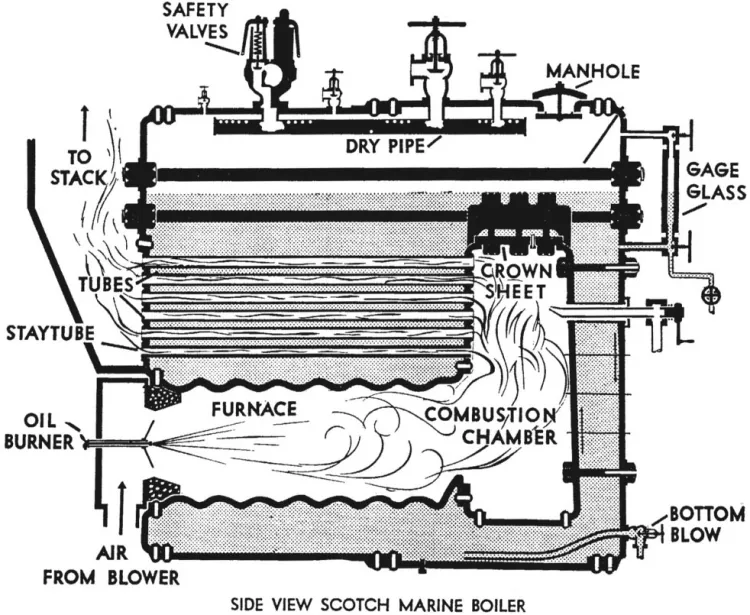

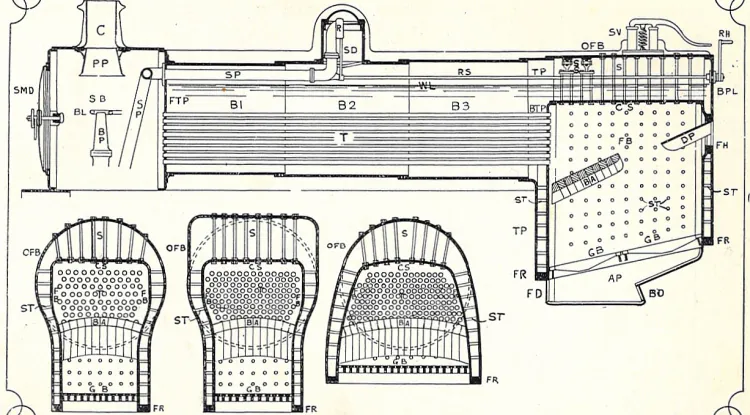

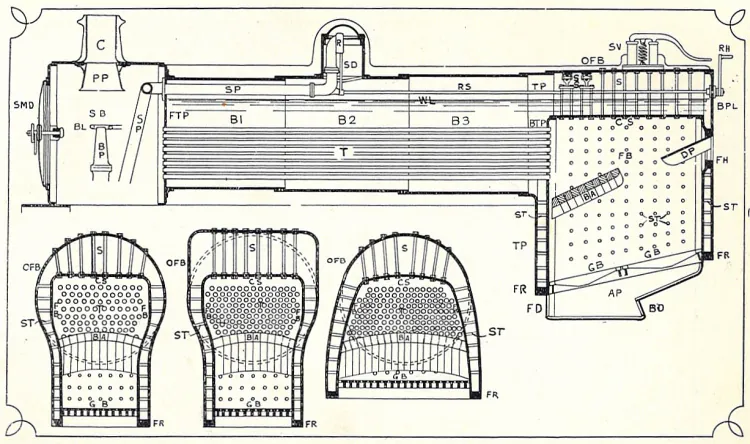

A locomotive Boiler is a Fire Tube Boiler. It is a horizontal drum axis, multi-tubular boiler. Because this boiler has 116 general fire tubes and 38 superheated fire tubes. A Locomotive Boiler is an internally fired boiler. That means the boiler furnace is located inside the main boiler shell or barrel. This boiler uses solid fuel like coal. It is also a forced circulation, mobile or portable type, and medium-pressure fire tube boiler. The most common use of this boiler is in railway locomotive engines and the marine sector because of its mobility. This boiler has a high steam generation rate.

Construction of Locomotive Boiler:

A Locomotive Boiler has several components. First of all, it’s a shell or barrel. Generally, the boiler shell diameter is about 8.5m and the length is about 4m. A Steam Dome is present at the top section of the boiler. It contains the regulator for regulating the steam produced through the steam pipe when the boiler is operational.

A firing point or hole is present at the rear end of the boiler. We already know that this boiler uses solid fuel in a furnace. Solid fuel is inserted and ignited into the furnace by using this hole. After that, a firebox is present inside the boiler shell where the fuel is burned and generates heat. There is a platform called Grate where solid fuel like coal is kept and burnt.

It is a fire tube boiler and we already know how many fire tubes are present inside this boiler with its types. The fire tubes in which, the hot flue gases pass. When hot flue gases pass they exchange the heat with surrounding water. There is a smoke box and it is the only way where smoke is passing through the air. When solid fuel is burned inside the furnace it also creates some smoke. This smoke needs to exhaust into the environment by the chimney.

There is a fire brick arch placed inclined over the grate. It is responsible for preventing the entry of ash, burnt fuel, and dust particles into the fire tubes during operation. Brick arch also provides a way for the hot flue gases to travel a definite path before they enter the boiler fire tubes. There is a pipe called Steam Pipe. By this pipe generated steam passes through. There are two steam pipes in Locomotive Boiler. The first one is the main steam passing pipe. It is located between the superheater and the dome. The second steam pipe connects the superheater exit end to the steam engine.

Related:- Lancashire Boiler - Construction, Working Principle With Advantages and Disadvantages

A blast pipe is provided above the steam engine. By this pipe, the exhaust steam passes. It has an important role during boiler operation. Generally, a blast pipe is used to create the artificial draft that pushes the smoke out through the chimney. It also creates suction pressure for the hot flue gases. This suction pressure allows the hot flue gases to pass forward and it passes through the boiler fire tubes.

This boiler has a Super-Heater and it superheats the steam to the desired temperature. Steam used to be superheated before it entered into the cylinder of the steam engine. Because wet steam is harmful to the engine. There is a superheater element pipe by which the steam travels and becomes superheated.

The safety valve is used for safe working with steam pressure. This safety valve is responsible for blowing off steam when the pressure of generated steam increases above the safety level or critical level. It also prevents the blasting of the boiler. There is a Regulator valve present that regulates the steam through the main steam pipe for superheating. Now come to the final component of this boiler and it is Chimney. It is used to throw out the exhaust smoke and gases to the environment.

Working of Locomotive Boiler:

The locomotive boiler uses solid fuel like coal. At first, the solid fuel is inserted into the grate. Then it ignites from the fire hole. When the fuel is burning inside the fire hole, it starts to generate necessary hot flue gases. Then a fire brick arch provides the path to flow the hot flue gases to a definite path before it enters into the long fire tubes of this boiler. As we know it also stops entering the burnt solid fuel particles into the fire tubes during the operation of the boiler. You will find two air in the damper to flow fresh air into the combustion chamber.

When hot flue gases pass through the boiler fire tubes they heat the water surrounding the fire tubes. Water becomes heated by this continuous process and water becomes saturated steam. Generated saturated steam is collected at the top. Then this saturated steam from the dome (which is present at the top of the boiler) enters into the main steam pipe through the regulator valve. After this stem steam travels through the main steam pipe and reaches the super-heater header. From this super-heater header, steam enters into another pipe called the superheater element pipe. It is the place where saturated steam becomes superheated. Then superheated steam enters into the steam pipe of the smoke box.

When saturated steam becomes superheated then it goes to the cylinder containing the piston. By this superheated steam engine piston moves inside the cylinder. Piston used to connect with the wheels of the steam engine and the wheels start rotating like a locomotive train. Then the exhaust steam from the cylinder enters the blast pipe. When you are sending steam into the cylinder then only steam will come out as exhaust gas.

Burnt gases and smoke after passing through the fire tubes of the boiler then it enters the smoke box. Then the exhaust steam comes out from the blast pipe and it pushes the smoke out of the boiler through the chimney. Smoke from burned solid fuel cannot escape from the boiler on its own. For this reason, an artificial draft is created by exhaust steam coming out from the steam engine cylinder. This artificial draft also pushes the smoke out of the smoke box and creates suction pressure for the hot flue gases. There is a platform under the Grate called an ash pit where ash is stored after the burning of solid fuel.

Application of Locomotive Boiler:

Locomotive boilers are mostly used in railways and marine sectors. But the efficiency of this boiler is very low. This boiler cannot work in heavy load conditions. Locomotive Boiler is also used in traction engines, portable steam engines, steam rollers, and some other steam road vehicles.

Now come to the Advantages and Disadvantages of Locomotive Boiler:

The best advantage of this boiler is it's portable. Because you can take and place this boiler at any place. The price of this boiler is less and it is capable of handling fluctuating demands of steam. This boiler has a high steam generation rate. It comes with compact and easy to operate.

After all those advantages it has some disadvantages like corrosion and scale formation. This boiler cannot work under heavy load conditions due to its overheating problems.

Now if you like this article then please share it with your friend. Thanks!