Vertical Boiler - Construction & Working Principles

Construction & Working Principles of a Vertical Boiler.

Generally, a vertical fire tube boiler is a vertical type boiler. In this boiler heating surface is composed of multiple small fire tubes and is arranged vertically. In this post, we will learn the Construction and Working Principles of Vertical Boilers.

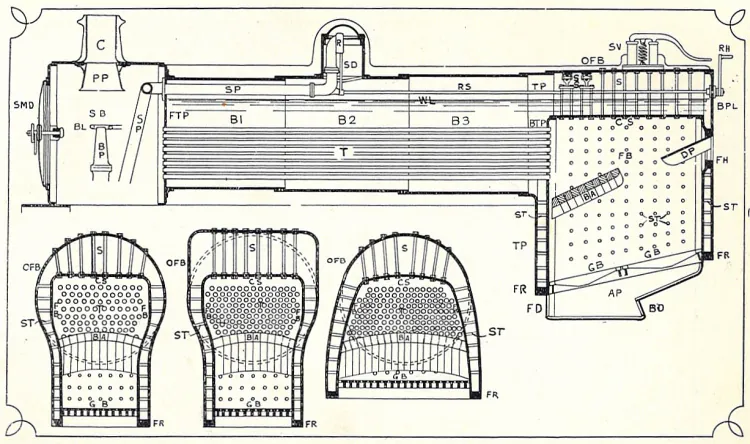

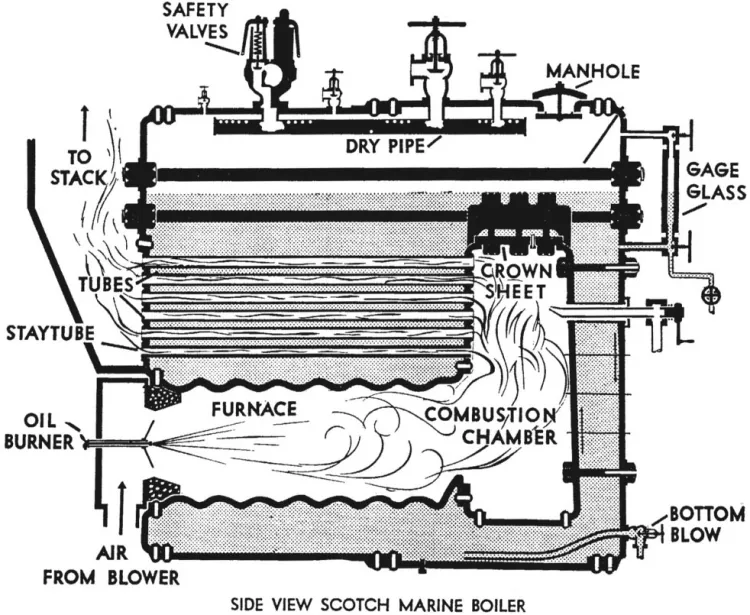

Construction of Vertical Boiler:

The interior parts of this boiler have been separated into four and those are,

- Furnace and Combustion Chamber.

- Water Chamber.

- Steam Chamber.

- Chimney.

Furnace and Combustion Chamber: The furnace is an important part of any kind of boiler. It is also called the heating surface for a boiler. Fuel is used to burn inside the boiler furnace and heat is generated. Then heat transferred to the water inside the boiler and became steam. A brick bridge is used inside the combustion chamber. By using this brick bridge less fuel is needed and the efficiency of the boiler is increased.

A corrugated shape will be found with the furnace plate. This corrugated plate is made with some metal alloy and its strength is very high. One of the main reasons is that it is the main heating section for this boiler. This plate thickness can be 1.54cm. It is one of the thin plates inside the boiler. For this reason, this plate can be heated so first heat transfer to the water is relatively high.

Related:- Locomotive Boiler - Construction, Working Principles With Advantages and Disadvantages

Water Chamber: This chamber contains water. After the water treatment procedure, feed water is stored in the water chamber. This feed water flows through the inside or outside of the tube and gets heated by the furnace-generated flue gases. After, this feed water becomes steam.

Steam Chamber: Generated steam inside the boiler is stored in this steam chamber when it is in the primary stage. From this steam chamber, steam is transferred to the superheater. Then superheated steam transfers to the prime mover. You can say saturated steam is stored in this steam chamber.

Chimney: When you are burning fuel inside the furnace then smoke and gases will be generated. By using the chimney this smoker and hot gases are released into the atmosphere. The boiler chimney helps to release all fly ash, and burn flue gases, and smoke into the open air. The boiler chimney needs to be long height that by using all smoke and gases can released at maximum height. For this height smoke and gases have less amount of negative in the environment.

To get a better efficiency of a boiler, a draft is needed at the furnace. Natural draft is created by the chimney and it helps to burn fuel in a furnace. If the height of the chimney is high then natural draft power will be high. But making a long-height chimney is much more expensive. For this reason, the long-height chimney is not available at present time. In modern boiler-induced draft fan (I.D Fan) is used to release smoke by the small chimney.

Working of Vertical Boiler:

When fuel is placed in the furnace and burned then hot flue gas is generated. Then these hot flue gases pass through the fire tube and heat the surrounding water. When water becomes heated then it is converted into saturated steam. You can call this saturated steam as a primary steam. This saturated steam is stored at the steam chamber. From the steam chamber is transferred to the boiler superheater. This superheating process makes saturated steam into working steam. After that super heated steam is transferred to the prime mover. All hot burn flue gases, smoke, and ash are released from the boiler by a chimney. The boiler chimney creates a natural draft to increase boiler efficiency.

Now if you find this post useful then please share it with your friends. If we missed any part to explain then please let us know in the comment section. Thanks!