Introduction of Industrial Chiller

A Chiller is a mechanical device designed to remove heat from a liquid. Typically water or a water-glycol mixture, to cool a space or process.

A Chiller is a mechanical device designed to remove heat from a liquid. Typically water or a water-glycol mixture, to cool a space or process. This process of heat removal is essential in various industrial, commercial, and residential applications where maintaining a specific temperature is crucial for equipment performance or human comfort.

The basic principle behind a chiller involves the circulation of a refrigerant through a closed-loop system. This refrigerant undergoes a cycle of compression, condensation, expansion, and evaporation, absorbing heat from the liquid being cooled in the process. Chillers come in different types, including air-cooled and water-cooled systems, each with its advantages and applications.

In an air-cooled chiller, ambient air is used to dissipate heat from the refrigerant. This type of chiller is often more convenient in smaller installations or where water availability is limited. On the other hand, water-cooled chillers utilize water from an external source, such as a cooling tower, to release heat. Cooling tower capacity will depend on the water flow required to cool the chiller. This design is often more energy-efficient but requires additional infrastructure.

Chillers find widespread use in air conditioning systems for buildings, data centers, and industrial processes such as pharmaceutical manufacturing, food processing, textiles, cold storage, etc. They play a critical role in maintaining temperature control in environments where precise conditions are necessary for the operation of equipment or the well-being of occupants.

Chillers are Generally of Two Types in the Industrial Sector:

- Vapor Absorption Type Chiller.

- Vapor Compression Type / Screw Electric Type Chiller.

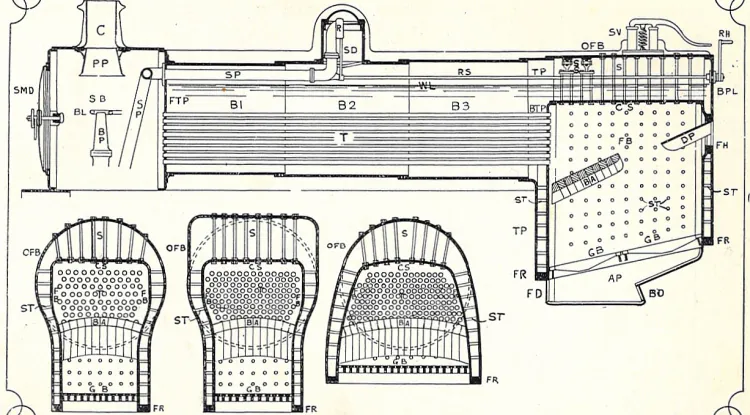

Now Come to the Main Parts of the Chiller:

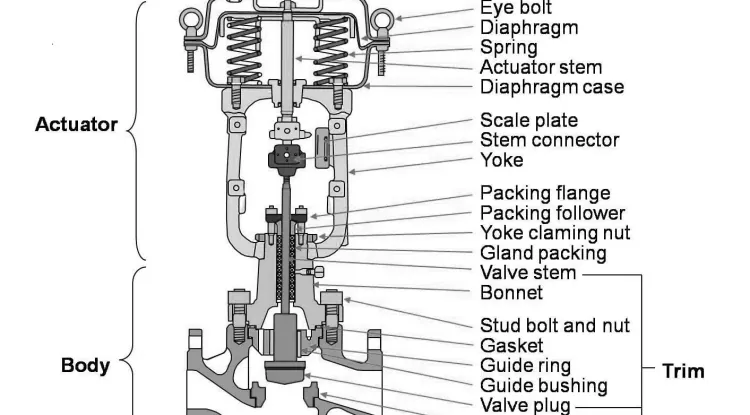

- Abosorber

- Evaporator

- Condenser

- Absorbent pump

- Refrigerant pump

- Purge pump

- Manometer

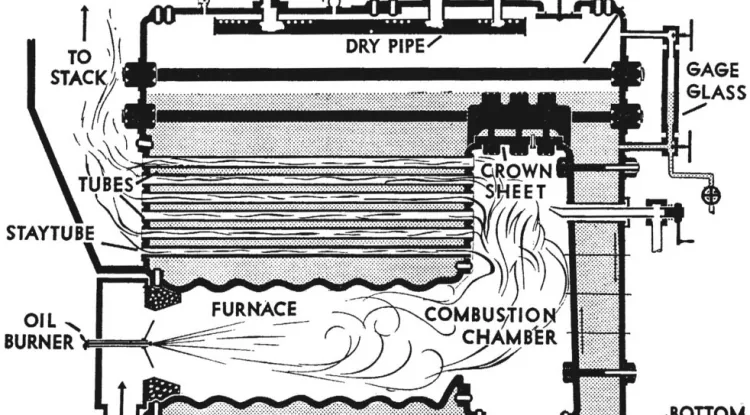

- High-Temperature Generator (HTG)

- Low-Temperature Generator (LTG)

Working Procedure:

Since water temperature is related to pressure. So when the pressure increases, the temperature also increases. The water temperature is 100°C at an atmospheric pressure of 760 mm Hg. Then the temperature of water at 6 mm Hg pressure is 3.7°C. Water evaporates at low temperatures due to a pressure of 6 mm Hg in the evaporator. The temperature required for vaporization is absorbed from the chilled water. As a result, chilled water is cold.

For example:

The vapor absorption chiller is usually kept vacuum. As a result, the r chilled water flows through the evaporator tube. As the chilled water flows through the tube, the refrigerant pump sprays the refrigerant onto the tube.

During spraying, the refrigerant evaporates by absorbing the necessary heat from the chilled water. Lithium Bromide is used to absorb the vapor. Lithium Bromide absorbs steam and mixes with water. HTG- High-Temperature Generator is provided to isolate this mixer. Due to the high temperature (150-155)°C in HTG, the refrigerant separates from the Lithium Bromide and enters the condenser. The refrigerant exchanges heat with the cooling water tube inside the condenser

Turns into liquid and accumulates in the refrigerant sump. Again the chilled water is sprayed on the tube through the refrigerant pump.

On the other hand, cold water is introduced through the condenser & condenser tube to reduce the temperature of the condenser & condenser. This process continues in cycles.

In summary, a chiller is a vital component of climate control systems, providing a means to regulate temperatures efficiently and effectively. Its applications range from creating comfortable living and working environments to ensuring the optimal functioning of industrial processes, showcasing the versatility and importance of this cooling technology in various sectors.