Type of Bearings, Constructions & Maintenance

The word bearing means any support for a rotating shaft or spindle. Bearings are load carrying mechanical machine components. No machine can run without a bearing.

The word bearing means any support for a rotating shaft or spindle.

Main Functions:

- To carry the load of moving parts

- To help the shaft for easy movement

- To reduce friction

- To help the shaft

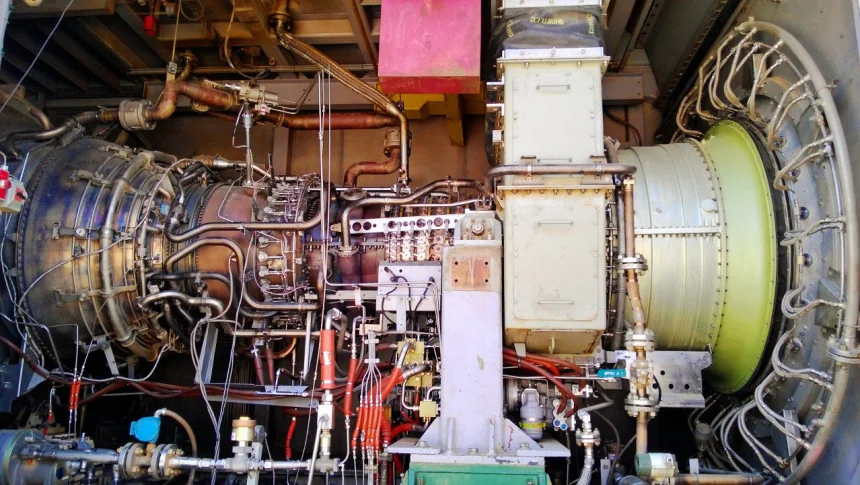

Bearing is used in all rotary machines such as pumps, turbines, compressors, fans, blowers, motors, generators, etc.

Types of Bearings:

Bearings are Mainly 02 Types:

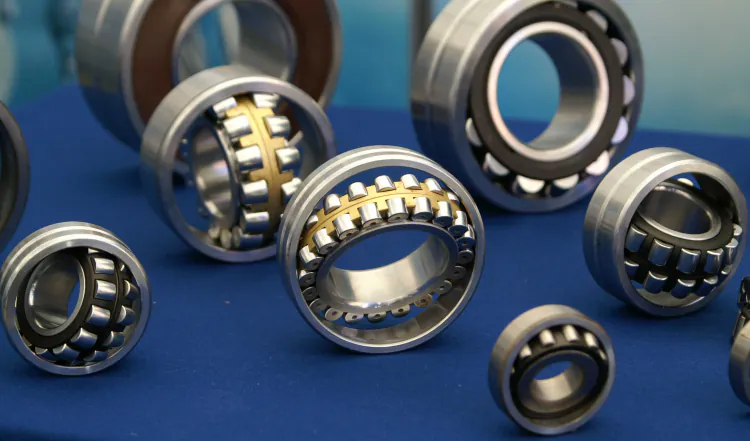

a) Anti-friction or rolling element bearings

1. Ball Bearing

- Deep groove ball bearing

- Angular contact ball bearing

- Self-aligning ball bearing

2. Roller Bearing

- Cylindrical roller bearing

- Taper roller bearing

- Spherical roller bearing

b) Plain or journal bearings

- Bush type

- Split type&

- Tilting pad type

Construction of Anti-friction Bearings:

Anti-friction bearings consist of:

- Outer ring

- Inner ring

- Ball /Roller

- Cage

- Inner ring raceway

- Outer ring raceway

Ball Bearing:

A ball bearing is a point contact bearing

Deep Groove Ball Bearing

- Balls are placed in the central groove of the rings.

- The race way (groove) is too deep.

- The shape of the two rings is similar.

- Can accommodate axial load also.

Angular Contact Ball Bearing

- Balls of this bearing contact at an angle with the central line

- Thickness of each ring is thick at the ball-seat side and thin at the other side

- Designed for combined loads (Radial& Axial)

Self-aligning Ball Bearing

- Balls (double row) are fixed on the inner ring

- This bearing is suitable for misalignment

Roller Bearing

A roller bearing is a line contact bearing

Cylindrical Roller

- The roller is a cylindrical shape

- Can accommodate heavy radial load

Taper Roller

- Roller is a taper

- Can accommodate heavy combined loads.

Spherical Roller

- Have two rows of rollers

- Self-aligning capability

- The diameter of the roller is maximum at the center, as a sphere

- High radial load & also can accommodate axial loads.

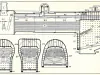

Types of Plain Bearing:

A Journal bearing is so named because it supports the journal of a shaft (The journal is that part of the shaft which rotates within a bearing).

- Bush Type

- Split Type

- Tilting pad Type

Bush Type

- The team bushing refers to the thin wall type bearing.

- Its strength comes from the thickness and rigidity of the housing.

- Most bushings are made of brass, bronze, gun metal, etc.

- Suitable for light loads & low-speed applications.

Split Type

- Split types bearings are generally divided into two parts.

- Split bearing can be replaced on a shaft more easily.

- Large diameter bearings are commonly this type.

Tilting Pad Type

- Consists of several babbitted bearings pads or segments (05 is the most common number) that are free to pivot.

- Generally used in very high speed machines.

- Tilting pad thrust bearing is also used in high-speed machines.

Maintenance of Bearing:

Inspection Parameters:

- Lubricant

- Sound

- Vibration etc.

Lubricant:

- Temperature

- Level

- Pressure

- Viscosity

- Color

- Cleanliness

- Flash point

- Pour point

Sound:

For hearing sound, we can use:

- Sound bar

- Electronic stethoscope

Vibration:

- By using this technique, we can find out:

- Status of bearing clearance

- Center position of the rotor in the bearing

- Oil film thickness etc.

Bearing Assembly:

Mechanical Process

- By bush & hammer

- By ram

Heating Process

- By oil bath

- By an induction heater

- By heating chamber

Bearing Disassembly

Mechanical Process

- By bearing puller

- By bush hammer

- By ram pressure

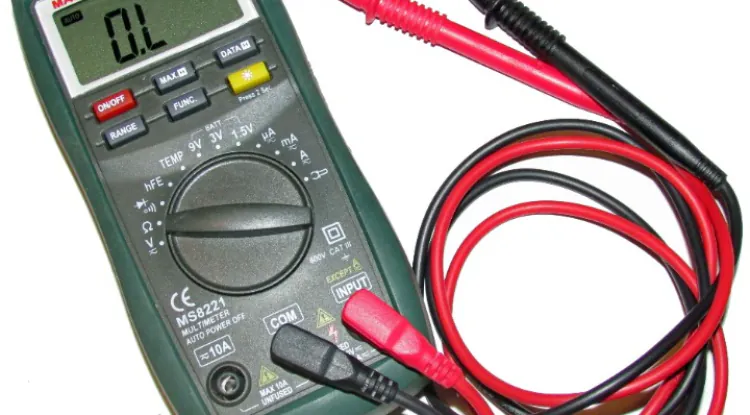

Bearing Clearance Measurement:

The rolling element bearing clearance is the clearance between the bearing rings and the rolling elements. This clearance is measured by feeler gauge.

The plain bearing clearance is the clearance between the journal and bearing. Plain bearing clearance can be measured as follows:

- Lead wire method

- Plastic wire method

- Dial indicator method

- By measuring the diameters