Scotch Marine Boiler - Types, Construction, Working Principles & Advantages

Types, Construction, Working Principles & Advantages of a Scotch Marine Boiler.

By the name of Scotch Marine Boiler, we can understand it’s a marine boiler. That means this boiler is used in the marine sector. Scotch marine boiler is one of the most common boilers which are used on ships. In this, we will learn about scotch marine boiler construction, the working principle with its advantages.

Scotch Marine Boiler:

First of all Scotch Marine Boiler is a Fire Tube Boiler. It is also a scotch or tank-type boiler. It is a common boiler in the marine industry. This boiler has some special advantages like its compactness and operation efficiency. Scotch Marine Boiler can use any type of water.

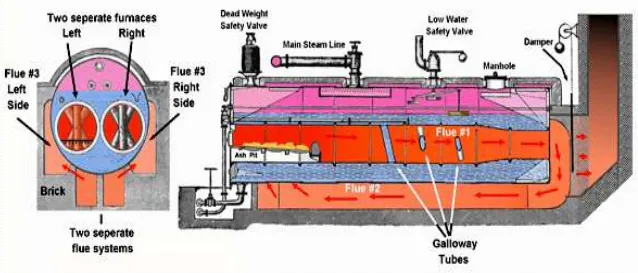

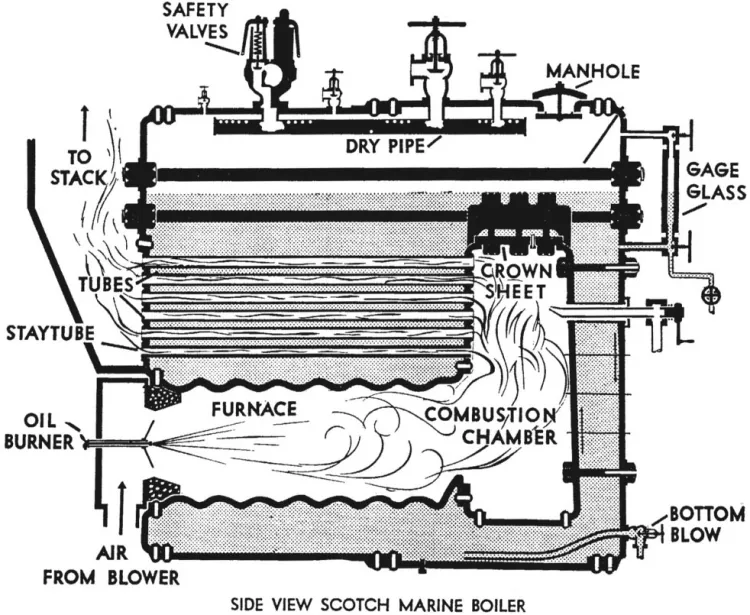

The general layout of the Scotch Marine Boiler is that of a squat horizontal cylinder. At the lower part of the boiler shell, one or more large cylindrical furnaces are present. Burned gases and smoke from the boiler furnace pass through the back side of this boiler. After that gases and smoke return through the small tubes and up and out through the boiler chimney.

Types of Scotch Marine Boilers:

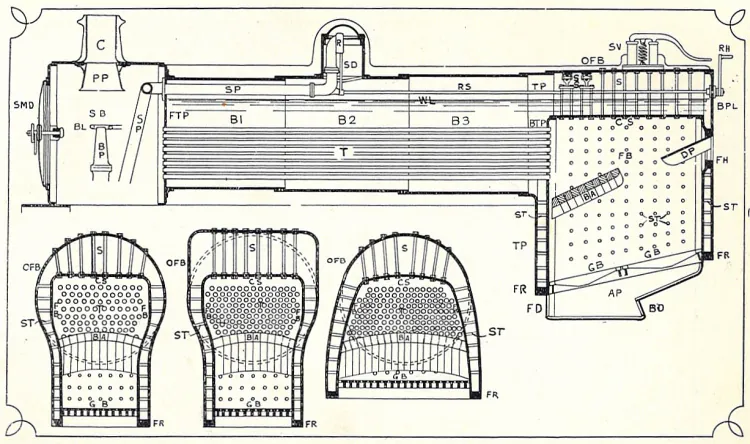

Single-Ended: Generally the single-ended steam boiler contains one to four furnaces. All these furnaces enter from the front part of the boiler. Normally the length of the single-ended steam boiler can be 3.5 meters.

Double-ended: Furnaces are present at both ends of this type of boiler. But several furnaces with a boiler vary from 2 to 4 in each end. Normally the length of a double-ended steam boiler can be 6.5 meters.

Construction of Scotch Marine Boiler:

This boiler consists of some basic components like other boilers. I am going to give you more details of each element. If I missed any of it then please let me know in comment.

First of all, it’s a Furnace, and like another boiler, it used to burn the fuel inside the boiler. We already know that a single-ended scotch marine boiler is fired with four furnaces. But each of the furnaces has its combustion chamber with it. Now come to another component which is the combustion chamber. It is one of the parts of the boiler where the fuel combustion normally takes place. You will also find plates in the combustion chamber. It requires the top plate, the back plate, two side plates, and the tube plate. There are some smoke tubes placed horizontally. All those smoked tubes connect the combustion chamber to the chimney.

Related:- Locomotive Boiler - Construction, Working Principles With Advantages and Disadvantages

The next component is the smoke box. This boiler has several smoke tubes. We already know that all are tubes placed horizontally and connect each other from the combustion chamber to the chimney. After fuel combustion, burned smoke passes through smoke tubes and then enters the chimney.

Like other boilers, Chimney is used to exhaust the burned gases and smoke out of the boiler during operation. Exhaust gases are released into the environment by the chimney. Another important component is the Boiler shell. It will be better if you know how the boiler shell is made. “Boiler - How It’s Made?” read this article and you will know how a boiler shell is made. It protects the internal parts of the boiler. Boiler shell size and thickness depend on the amount of pressurized steam required for the purpose.

Working of Scotch Marine Boiler:

The working of the boiler is very simple. It will take the fuel, burn it in a combustion chamber and water will be heated. After the heated water becomes steam. For this reason at first fuel is inserted into the furnace. The fuel passes through the furnace by a fire hole. When there is fuel in the furnace then it ignites through the fire hole. After that burnt fuel enters the combustion chamber is the place where the combustion of the fuel takes place. Now come to the heat transfer procedure. When the heat is generated in the combustion chamber then it is used to heat the water surrounding the combustion chamber. Again it is the basic heat transfer procedure for a regular fire tube boiler.

When water becomes steam, then it’s supplied to the steam turbine. Here we have some burnt flue gases and smoke that are created at the fuel combustion procedure and they need to be released into the environment. For this stem, the exhaust gases pass through the smoke tubes and reach the boiler chimney. Then the chimney releases all smoke and exhaust gases into the atmosphere. In this boiler, the water is used to surround the furnace, combustion chamber, and smoke tubes. For this reason, it provides a greater heating surface to the water during boiler operation.

Advantages of Scotch Marine Boiler:

This boiler has a great advantage and for this reason, this boiler is generally used in marine works and on ships. It is a compact size boiler and it has great efficiency in operation. Also, this boiler can generate steam from any type of water. Brickwork settings like Locomotive Boiler and external flues are not required in this boiler.

If you like this post, then please share it with your friends and let us know in the comments if we missed any part to explain. Thanks!