Cornish Boiler - Construction, Working Principles With Advantages and Disadvantages

Construction, Working Principles With Advantages and Disadvantages of a Cornish Boiler.

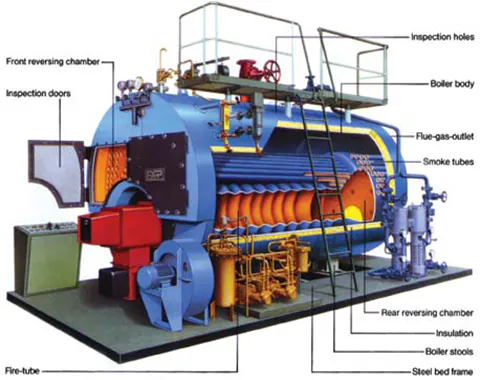

Cornish Boiler is a fire tube boiler. It was first adapted by Richard Trevithick and, was first installed at Dolcoath mine in the year 1812. This boiler has a long horizontal cylinder with a single large flue containing the fire. Cornish boiler design has a similarity with the Lancashire Boiler. But if you consider the performance then the Lancashire boiler will be ahead. Cornish boiler can produce steam at the rate of 6500 kg/hr and can take a maximum steam pressure of 10.5 bar. But in the case of Lancashire Boiler can produce steam at the rate of 9000kg/hr and can take a maximum steam pressure of 16 bar.

Cornish Boiler cylindrical shell is about 1.25 m to 1.75 m in diameter. The length of the shell can be varied from 4 to 7 meters. It has only one internal flue tube inside the boiler and the diameter of the flue tube is 0.6 times the diameter of the cylindrical shell.

Construction of Cornish Boiler:

This boiler is made with a long cylindrical external shell. This shell is made of steel plates. You will find only one internal flue tube in this boiler. But in Lancashire, there are 2 flue tubes. Then you will find a fire grate or so-called furnace. This furnace is located at the front side of the tube and it is also called the furnace tube. Normally coal is introduced through the fire hole into the fire grate.

Then you will find a brick arc. This brick arc is used to prevent the ashes and burning coal into the boiler's internal parts like a flue tube. But generally, brick arc deflects the flue gases upwards. Two flue tubes are located on two sides of the boiler shell and the third one is on the bottom section of this boiler. There is another flue tube is present. It’s called the main flue tube. Flue gasses enter the main flue tube and it leads to the boiler chimney.

A spring-loaded safety valve is mounted on the boiler. The main function of this safety valve is to release the excess steam pressure when steam pressure is very high in the boiler. When the pressure decreases and reaches the rated pressure inside the boiler then this pressure valve goes off. This valve is normally located at the top section of the boiler shell.

Related:- Scotch Marine Boiler - Types, Construction, Working Principles & Advantages

Then there is a stop valve and it’s located at the top of the boiler shell. The main function of this stop valve is to regulate the generated steam between the steam pipe and the boiler. A high steam low water safety valve is located near with stop valve. The main function of this valve is to release the generated steam when the water level falls below a certain level.

Next, there is a feed pipe which is controlled by a feed valve. It is used for feeding water inside the boiler uniformly when the boiler is so much heated. The steam generated carries a large quantity of water in the steam spaces and it’s called priming. Then you will find an anti-priming pipe. This pipe is providing to separate water as far as possible. Then a blow-off cock uses to remove the mud that is present at the bottom of the boiler. The water inside the boiler can be completely drained by this blow-off cock for inspection.

There is a main hole that is also used to inspect inside the boiler. A pressure gauge is attached to the boiler and by this, we can know the amount of pressure present inside the boiler when it’s operational. There are two dampers located on the two sides of this boiler. The damper is used to regulate the flow of air and it also controls the steam generation.

Working of the Cornish Boiler:

Coal started to burn inside the furnace and generated flue gas. Then flue gas passes through the boiler's internal flue tube. As we know this boiler has only one internal flue tube. This flue gas also passes through the main flue tube to the side and bottom flue tube. In this way, water around the flue tube becomes heated and generates steam. When steam is generated inside the boiler then it goes through the engine by the priming pipe. After that flue gases pass out through the chimney. The working principle of this Cornish boiler is very simple.

Application of Cornish Boiler:

This boiler is used in many industries like textile, sugar, paper, and some other small industries. It is also used to produce steam to run steam turbines and it can be found in marine industries.

Advantages and Disadvantages of Cornish Boiler:

By this article, you already know that this boiler has a simple design and easy construction. It is a compact and portable boiler. The construction and maintenance cost of this boiler is very low and it can overcome load fluctuation during operation. But it has a low steam production rate = 6500 kg/hr and the maximum steam pressure range is 10.5 bar. This boiler needs more ground because of its horizontal structure.

Now if this post is useful then please share it with your friends. Thanks.